Slurry Pump Solutions in Michigan

Your Trusted Industrial Slurry Pump Specialists Across the Great Lakes State

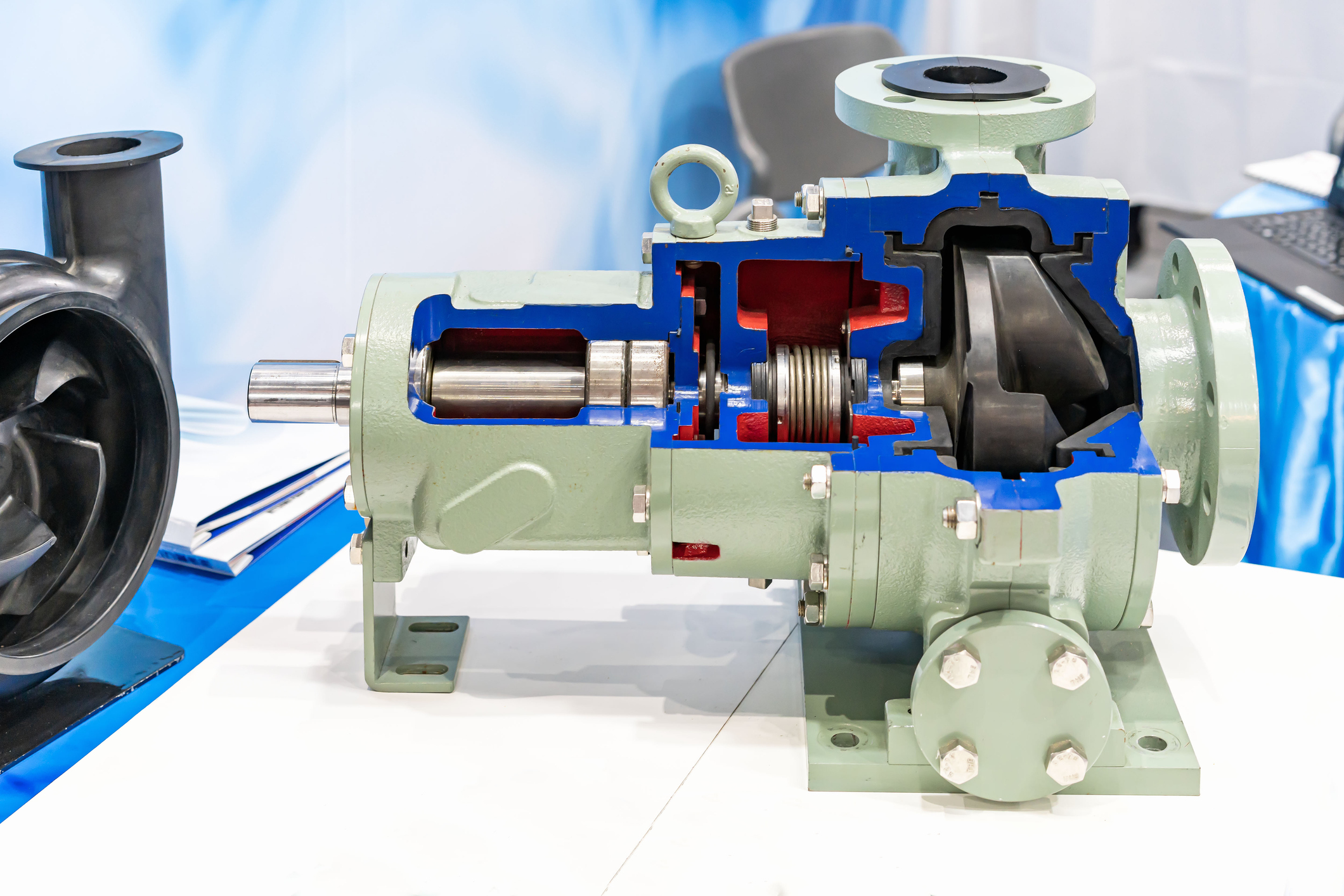

At ProSeal Service Group, state-of-the-art mechanical seal products are a way of life. After more than two decades, our partnership with AESSEAL®—a world specialist in mechanical seal R&D—has granted us exclusive rights to distribute in Michigan, Ohio, and Alaska. This allows us to deliver some of the most technologically advanced seal products in Component, Single Cartridge, Double Cartridge, Split, Metal Bellows, Mixer, and API seals to keep you operational.

Ready to solve your toughest slurry handling challenges? Contact our Michigan team today for expert consultation and custom pump solutions.

When Michigan's industrial operations demand reliable slurry handling solutions, experienced professionals turn to proven centrifugal pump technology, backed by our ongoing commitment to pump design and engineering innovation.

Michigan's diverse industrial landscape requires specialized pumping solutions that handle abrasive materials, high-solids content, and challenging operating conditions.

Our industrial slurry pumps are engineered to withstand the rigorous demands of mining operations, wastewater treatment facilities, power generation plants, and manufacturing processes throughout the state. We also provide robust pumping solutions for commercial applications and construction sites, ensuring reliable performance for business-critical and infrastructure projects.

Why Michigan Industries Choose Our Slurry Pump Solutions

Proven Performance in Michigan Conditions: Our slurry pump systems are designed to handle the challenging conditions common in Michigan's industrial applications. Whether dealing with iron ore tailings in the Upper Peninsula or handling industrial waste in metropolitan Detroit, our pumps deliver consistent performance year-round.

Comprehensive Product Range: We supply a complete line of centrifugal slurry pump configurations to meet diverse application requirements:

- Horizontally mounted centrifugal slurry pumps for high-volume applications

- Vertically mounted slurry pumps for sump and pit installations

- Submersible slurry pumps for underwater operations, offering advantages over other pumps by operating fully submerged and pushing fluids from below the surface

- Heavy-duty slurry pump models for extreme service conditions

Each pump unit is engineered for reliability and quality, whether supplied as a single unit or in bulk orders.

Expert Technical Support: Our Michigan-based technical team provides comprehensive support from initial system design through ongoing maintenance. We understand local operating conditions and can recommend the optimal slurry pump configuration for your specific application requirements.

Rapid Response Service: Minimizing downtime is critical for Michigan's industrial operations. Our strategically located service centers across the state ensure quick response times for emergency repairs, routine maintenance, and parts replacement needs.