Mechanical Seal Repair in Pontiac, MI, & Kenai, AK

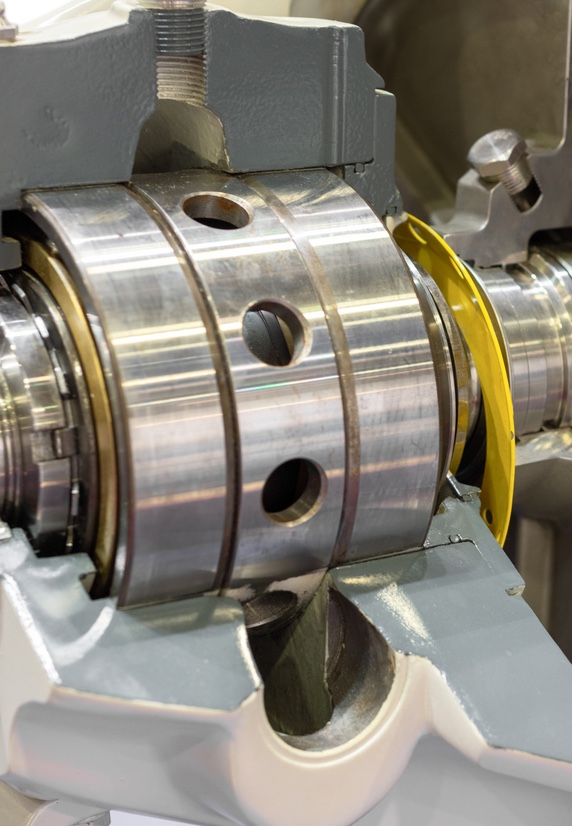

Precision Repair for Critical Seal Performance

When a seal fails, the entire system feels the impact. Leaks, downtime, and extra costs can put real pressure on your operation. That is why professional seal repair is essential. Pro-Seal Service Group restores seals with precision machining, cleaning, and polishing so your industrial pump and equipment run smoothly without the expense of constant replacements.

We work with seals from a wide range of manufacturers and applications, delivering repair services that keep critical equipment in service longer. With decades of experience and the right tools on hand, we provide fast turnaround, consistent quality, and results you can count on.